(excuse the pun, please)

This is an exercise in Computational Solid Geometry (CSG) - albeit in 2 dimensions.

The Fab Lab logo is a nice combination of geometric shapes - crying out for scripting - it's a cube, with a circle on each face, projected through its longest diagonal axis to create a 2-D pattern, in turn inscribed in a circle...

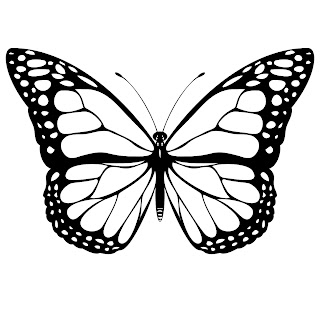

In short, it looks like this:

So, I started scripting - draw a square (for a side of the cube), draw a circle in its centre, connect the circle to the edge; shear the square so it looks like the projected edge of a cube; rotate it 120 and 240 degrees to make the three visible sides; put it in a circle, joined up at the edges and with a square round the whole thing.

The scripting language is "python", using Neil Gerschenfeld's cad.py module for creating and manipulating the laser cutter.

Since this got a bit tedious, I exported an image (as a .png) and imported it into Inkscape so I could use a mouse to change the size and the properties.

So, if you see anyone in the Fab Lab using a neat logo as a coaster, now you know how it was created.

--

The script:

#

# define part

#

# FabLab Logo

# parameters - for unit-length side

chanwidth = 0.5 # width of channel in side of cube

cubeside = 0.95 # how much of circle to fill with cube

spokewidth = 0.05 # the three radial spokes

holesize = 0.6

lc = circle(0, 0, 1);

sc = scale_xy(lc, 0, 0, holesize);

spoke = rectangle(-spokewidth/2, spokewidth/2, -1, 0);

sq = rectangle(-1, 1, -1, 1);

chan = rectangle(-(chanwidth/2), (chanwidth/2), -1, 0);

hole = add(chan, sc);

side = subtract(sq, hole);

sside = move(scale_xy(side, 0, 0, 0.5), 0, 0)

# shear_x_y(part, y0, y1, dx0, dx1)

dx = 1/sqrt(3.0);

sh= shear_x_y(sside, 0, 1, 0, -dx)

clipper = rectangle(-2, 2, -0.433, .433)

tfside = intersect(sh, clipper) # this is now unit sided

rtfside = rotate(tfside, -30) # right side is vertical

face = add(scale_xy(move(rtfside, -0.433, -0.25), 0, 0, cubeside), spoke)

face2 = rotate(face, 120)

face3 = rotate(face, 240)

front = add(face, add(face2, face3))

def xor(p1, p2):

part = subtract(add(p1, p2), intersect(p1, p2))

return part

logo = xor(lc, front)

border = 1;

xstart = 0;

xmax = 2;

ystart = 0;

ymax = 2

def coaster(s): # square size in inches

cifrac = 0.9; # fraction of logo circle

xstart = 0

ystart = 0

xmax = s

ymax = s

logos = scale_xy(logo, 0, 0, cifrac)

part = xor(logos, rectangle(-1, 1, -1, 1))

parts = scale_xy(part, 0, 0, s/2)

parts = move(parts, s/2, s/2)

return parts

xstart = 0

ystart = 0

xmax = 4

ymax = 4

gik = coaster(3.5)

#

# define limits and parameters

#

cad.xmin = xstart - border # min x to render

cad.xmax = xmax + border # max x to render

cad.ymin = ystart - border # min y to render

cad.ymax = ymax + border # max y to render

dpi = 50 # low resolution for previewing

# dpi = 200 # high resolution for machining

nxy = int(dpi*(cad.xmax-cad.xmin))

cad.nx = nxy # x points to render

cad.ny = nxy # y points to render

cad.inches_per_unit = 1.0 # use inch units

cad.view('xy') # show xy view

#

# assign part to cad.function

#

cad.function = gik